FAQ’s

Do I need Oversize or Undersize bearings?

Oversized = Same inside diameter with more material added to the outside of the bearing (Block or Rods have been increased or bored).

Undersized = Same outside diameter with more material added to the inside of the bearing (Crankshaft journals have been reduced or cut).

Do I need Aluglide, Race Series or Duraglide?

- For OEM build use Aluglide (Bi-metal A Series)

- For performance builds with bearings running crankshafts that have fillets and where engines run in the medium to high RPM range, use the Race Series (Tri-metal H Series with chamfered edges and ¾ oil grooves).

- Duraglide (Tri-metal P is the stiffest bearing we offer without chamfered edges and ¾ oil grooves). If contact patterns obtained with the Duraglide (P series) parts are too narrow, H (Race Series) bearings should be used. Contact pattern should ideally cover 2/3 to 3/4 of the bearing surface.

If you aren’t sure which type of performance bearing to start with, the H (Race Series) will be your best choice.

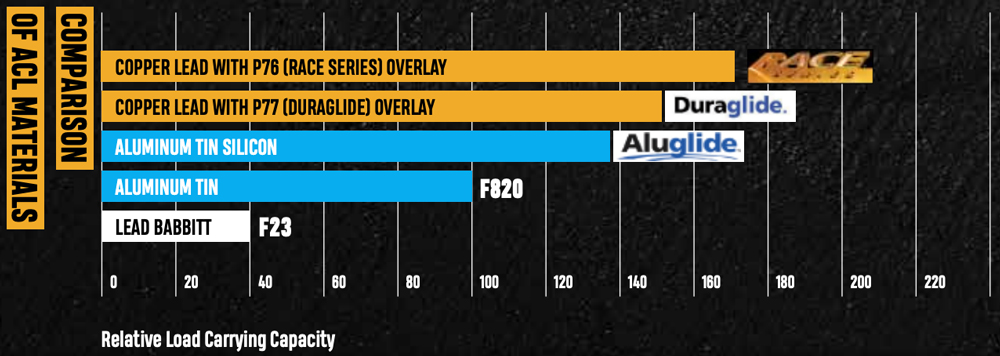

What is the relative load carrying comparison of ACL materials?